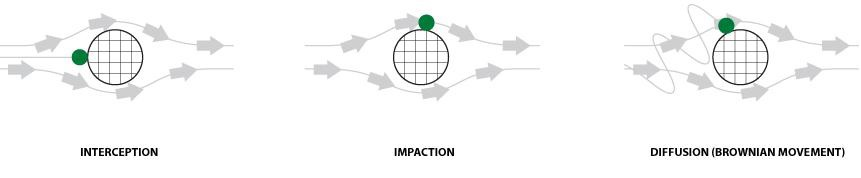

Collection is achieved by trapping the droplet between two adjacent filaments or fibres. The finer the filaments, the more there can be in a filter with less space between them, which increases the rate of interception of finer mists. At higher velocities interception is a mechanism of coalescene, but at lower velocities it aids collection.Normal velocity range for Interception is 0.2 to 0.8 m/Sec.

The mechanism whereby a particle or a droplet cannot avoid hitting a plate surface or one of the fibres / wires or vanes randomly arrayed in the path of the gas, even though the fast flowing gas tries to ‘streamline’ past. There is a relationship between the blade design and spacing or diameter of wire and the size of droplet collected. The range of velocities is broad (1 to 10m/Sec) without affecting efficiency.

At low velocities (usually below 0.2 m/Sec but maximum 0.25 m/Sec), as the gas passes horizontally through a bed of very fine fibres, the fine mist particles are bombarded by the gas molecules surrounding them, causing the particles to move in various directions, both towards and away from the fibres. The high number of fibres means. however, that the mist is virtually certain to collected on the fibres. The smaller the fibre diameter, the finer the mist size that can be collected.

The three major mist elimination methods are impaction, interception and Brownian movement.

Impaction depends on the particle having a high enough kinetic energy (a combination of particle velocity and mass) to allow the particles to leave their own slip stream, move across other flow stream lines, and impact against a target where it can coalesce with other droplets already collected at the target. Surface tension maintains the droplet on the target where it continues to coalesce with other droplets until it is sufficiently large for other forces (such as gravity or vapor shear) to overcome the surface tension and displace it.

Interception occurs when the deflected vapor stream passes the target within a distance less than the radius of the particle.

Collection with Brownian movement depends on the natural random movement of molecule-size particles. These randomly-moving particles are deflected and coalesced as they collide with targets and other droplets. As a mist passes through a bed of targets, the statistical probability of a particle coalescing on the targets can be predicted based on the nature of the bed of targets and its thickness, the particle sizes, and the time the vapor is in the bed.

These calculated statistical probabilities have been verified by laboratory and field measurements. With the Brownian movement mechanism, collection efficiency is enhanced with a slow superficial velocity trough the bed; whereas in the impaction method described above, removal efficiency is enhanced with a higher superficial velocity. Attempts to collect submicron mist particles predictably and efficiently using internal separation mist eliminators (mesh, zigzag baffle, and centrifugal cyclone separators) have been unsuccessful. The critical and practical limitations of velocity, differential pressure, and available kinetic energy required prevents achieving the high (99+ %) removal efficiency normally required in LOV applications.

All three mist removal mechanisms have inherent limitations on the maximum velocity that can be handled without allowing re-entrainment. Interception and impaction devices also have turn down limitations, such that collection efficiency decreases significantly if the air velocity is reduced.

However, the Brownian diffusion devices have no turn down limitation. A slower superficial velocity gives the particles more time within the bed which results in a higher efficiency of collection and coalescing of the oil mist.

Cartridge filters and electrostatic precipitators (ESP) have been successfully used to remove submicron particles. Both, however, have onerous maintenance requirements.

Cartridge filters can be successfully interrupt and collect the submicron particles. Prior to becoming saturated with oil, cartridge filters can successfully eliminate the submicron mist from the vapor. For continued efficiency, however, the filters must be replaced before they get saturated with oil.

The time period for saturation is frequently quite short. If a saturated filter is not replaced, a portion of the removed mist will be reentrained into the exhausted vapor, reducing the removal efficiency significantly.

ESP units can be highly efficient at removing submicron particles, but they require continuous maintenance to retain their efficiency. They require periodic cleaning of the plates and wires, plus monitoring (replacement and/or adjusting) of the transformer and electrical circuitry. The possibility of fire and explosion of electrical devices used near or within an oil aerosol is a hazard that should be given ponderous consideration before select-ing an electrostatic precipitator for oil mist removal. Indeed the potential hazards of the ESP unit eliminate them from consideration in many oil mist removal situations.

Other devices employing mechanically induced centrifugal force and combinations of mesh and filters have displayed limited removal efficiency.

In general, they have succumbed to decreasing efficiency with time, frequent and costly maintenance of the mechanically moving apparatus, sealing problems, and the need for frequent replacement of components.

Meanwhile, their success in submicron mist removal remains limited.

FIBER BEDS

Fiber bed mist eliminators use Brownian movement to coalesce and remove mist particles. They are designed and fabricated specifically to coalesce and remove submicron particles. When the design is correctly adjusted for the parameters of the specific application, fiber beds can achieve 99+% — even to up to 99.99% — removal of submicron (0.3 to 0.5 µ diameter) particles.

An early application of fiber bed mist eliminators was the removal of aerosol mists from vapors in sulfuric acid plants, where the submicron aerosol mists generated by the process can be highly corrosive and toxic. High re-moval efficiency required to protect equipment and the atmosphere. Fiber bed mist eliminators have been suc-cessfully removing submicron mists in this service for many years.

The proven technology and equipment for removing submicron mists from sulfuric acid plants was a natural solution to the LOV problem. After modifying the design to account for differences in the particle size distribu-tion curve, concentration of particles, differential pressure limitations, density of liquid, and total load, the fiber bed was successfully applied to removing LOV mist. In fact, for control of emissions from lubrication oil vents, fiber bed mist eliminators fall into the Environmental Protection Agency category of “Best Available Control Technology”.

Fiber bed mist eliminators achieve and maintain their high efficiency at high loads with a very low differential pressure. The required differential pressure is usually between 2 to 4 in. (51 to 102 mm) W.C. for installations that operate without a fan, or 6 to 10 in. (152 to 254 mm) where a fan is needed to maintain a negative pressure on the reservoir.

To provide a good experience, we use technologies such as cookies to store and/or access device information. When you consent to these technologies, we may process data such as browsing behavior or unique identifiers on this website. If you do not consent or if you withdraw your consent, this may adversely affect certain features.